Originally posted by dogbert

View Post

Announcement

Collapse

No announcement yet.

EK Ballast Install

Collapse

X

-

That part is done, I think I can top it off some times when it gets a little low. It would be easier and cheaper to complete.

-

Makes sense. No check valves for me then. KISSOriginally posted by chpthril View PostI think it would cause a hose to collapse once the bag is empty, if it the vent does not vent both ways. Draining from the bottom should allow the water to collect around the valve till near gone before sucking air. Because you are not draining out the side, you dont know when the bag is empty till the pump runs dry long enough to kick the run-dry switch. I dont think these pumps where intended to operate this way.

Of course, drilling holes in the bottom of my boat is never simple

Leave a comment:

-

Thanks all for your comments and expertise on the matter. It is a nice sunny day, about 60 today, and I think I will have some fun after work tonight trying to get some of it done.

I need to figure out the electrical problem first, then hook all the wires and pumps. I'll post some pictures later.

Leave a comment:

-

Originally posted by dogbert View PostThe last one is probably the best, except I'd add a check valve on the vent line so you always only have water in your Fly-High Sack. That way you will never suck air.I think it would cause a hose to collapse once the bag is empty, if it the vent does not vent both ways. Draining from the bottom should allow the water to collect around the valve till near gone before sucking air. Because you are not draining out the side, you dont know when the bag is empty till the pump runs dry long enough to kick the run-dry switch. I dont think these pumps where intended to operate this way.Originally posted by eks View PostWhat would that do to the pumps when there is nothing to suck? I know it sounds funny! "D

Would put too much stress on it?

Leave a comment:

-

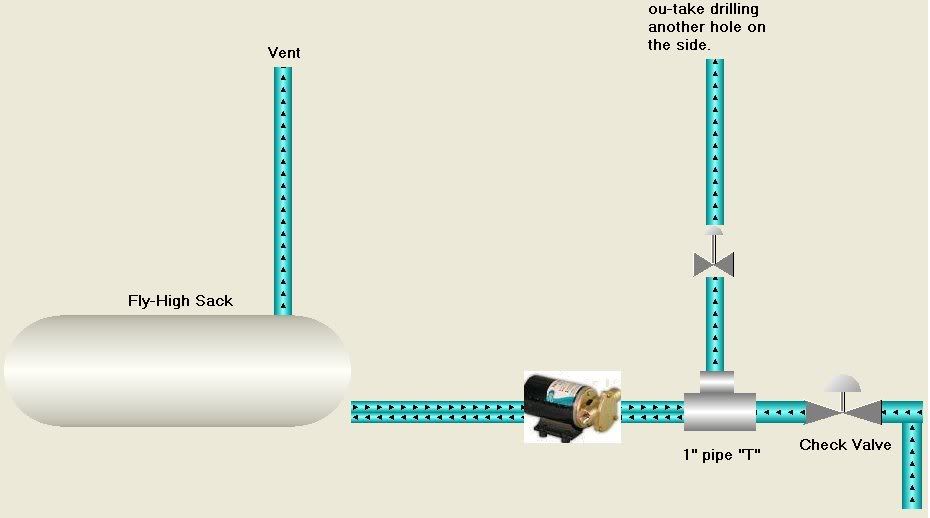

The last one is probably the best, except I'd add a check valve on the vent line so you always only have water in your Fly-High Sack. That way you will never suck air.

Leave a comment:

-

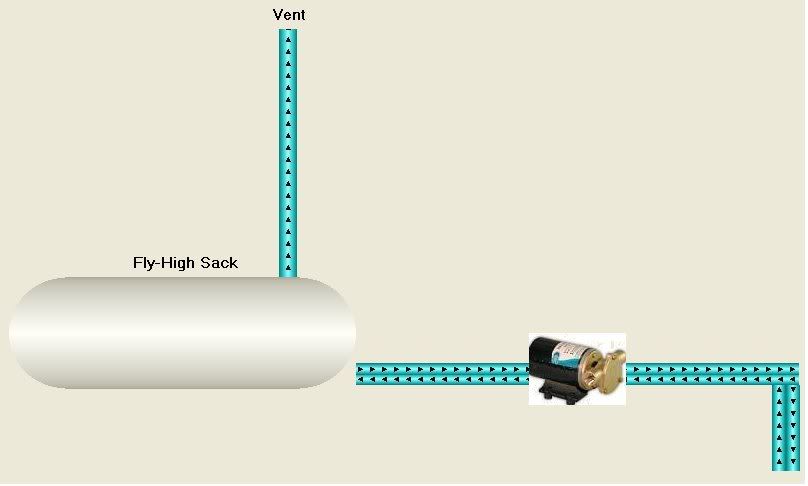

Here are a couple more designs.

I personally think that this clean schema would work and since there is less part, less possibility of leaks and parts breaking...

Leave a comment:

-

I would think draining from the top of the bag would cause issues if you used more than one hose into the bag if you were vented at all.Originally posted by SPBFAN View PostIf it were me I would put flapper check valves and only flappers. The beauty of this system is that you can build it the way you feel most comfortable with. You get the basic parts and add accordingly.

I personally think that check valves are not needed and I wonder if you could drain from the top of the bag which I bet you could. If you can I would fill and driain from there and leave it that way, then run with it, topping it off as needed. It is not like you are going to run out of water when on the lake to top off if needed. I personally would you the KIS theory. KIS. but if you really want me to I will work on a design with check valves.

Also, if you don't have vents coming out of the side of your boat, how do you know when you're full?

I still think you're better off not having check valves, with the exception of a check valve for the vent (to avoid sucking air).

Leave a comment:

-

If it were me I would put flapper check valves and only flappers. The beauty of this system is that you can build it the way you feel most comfortable with. You get the basic parts and add accordingly.

I personally think that check valves are not needed and I wonder if you could drain from the top of the bag which I bet you could. If you can I would fill and driain from there and leave it that way, then run with it, topping it off as needed. It is not like you are going to run out of water when on the lake to top off if needed. I personally would you the KIS theory. KIS. but if you really want me to I will work on a design with check valves.

Leave a comment:

-

I might just do it the original way not using any check valves and topping it off if gets too low. It would save money and time.

I am just going to wait to see what Andrew comes up with.

Leave a comment:

-

My pool has a check valve that failed after 8 years. I think it failed due to excessive chlorine and the fact that the spring mechanism was not well designed. I have a flapper valve now and it works much better, not to mention improving the flow of water.Originally posted by talltigeguy View PostIf you put a check valve between the pump and the manifold, then you cannot drain since these pumps drain out of the same hose that they fill with. Water has to go both ways at that point.

This system does not have a true 'manifold'. I assume that you mean the collection of PVC immediately attached to the through hull?

One question no one has asked here is this: All of this puts a strain that is pretty significant on the check valves, for a significant amount of time. Are the check valves durable enough that they can handle this? I have not heard much of check valve failures, but I am sure it might happen.

I still don't see the need for any check valves. If you see the automatic system in the MC boats, you'll notice that they are always topping off because there is always a little backflow.

Leave a comment:

-

If you put a check valve between the pump and the manifold, then you cannot drain since these pumps drain out of the same hose that they fill with. Water has to go both ways at that point.Originally posted by xpjim1 View PostYou will only need 2 check valves per pump. One between the manifold and the pump...

This system does not have a true 'manifold'. I assume that you mean the collection of PVC immediately attached to the through hull?

One question no one has asked here is this: All of this puts a strain that is pretty significant on the check valves, for a significant amount of time. Are the check valves durable enough that they can handle this? I have not heard much of check valve failures, but I am sure it might happen.

Leave a comment:

-

I see no need for three check valves. G said the amount of water lost out of the bags was minimal and they topped off quickly. Just side not depending on what MasterCraft boat you are looking at depends on if they drain from the vent hole or from the bottom of the boat. the one I looked at drains from the bottom of the boat. This can be corrected easily and drain from the side of the boat using the vent that is already installed. You would not have to create another hole in the boat any where at this point. It would all be placement of check valves. If I get the time I will draw it up and post it. It will be this evening.

Leave a comment:

-

But I can see your concern if filling. I still think you will be ok when you have the water flowing thru the pump

Leave a comment:

-

That third check valve is not necesary as that is the water flow direction. The water will not allow air to enter when draining

Leave a comment:

Leave a comment: