Sorry, I need to vent to folks who will understand.

I'm way behind on getting our new 24Ve ready for its first season. I only get to work on it for a short time after work on some weeknights. I'm starting to worry I won't be done by July 4th!

So today, I take the afternoon off to dedicate solely to making progress. I have all the tools. I have all the materials. I have an itemized list and a plan.

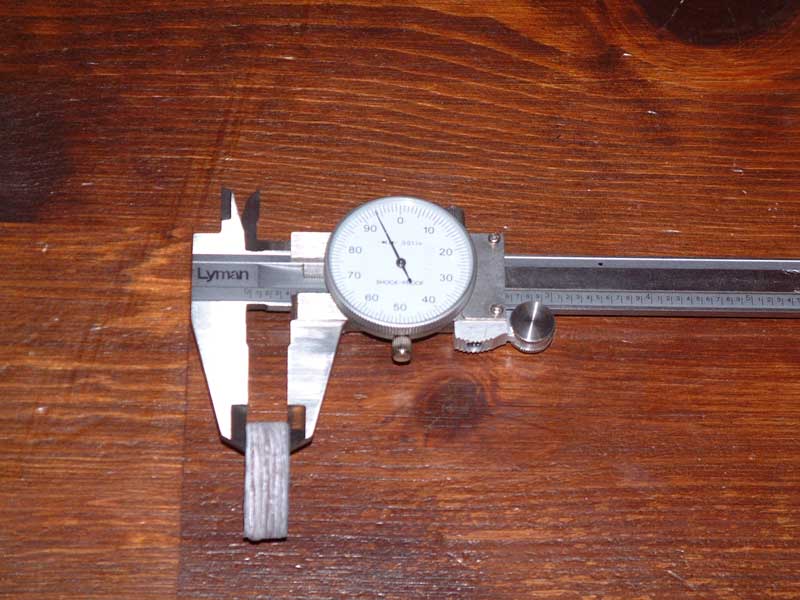

First up: Build some backing plates for my thruhulls. I measure and discover that the threads aren't long enough to permit the use of backing plates... if I install plates, there won't be enough exposed threads for the valves to screw onto them. Strike one.

OK, might as well start installing the valves and pumps. Oops, no pipe dope. It's at the lake house. Strike two.

Fine, I'll install the custom made grab handle/tow ring that I ordered from the same fab shop that made the original for this boat for Tige. Waited three weeks for it to be made. I tape off the transom, line up the new handle so I can mark for the two new holes that support the tow ring... and discover that the outside studs are too wide. They don't fit in the existing holes, just enough that if I enlarge the holes the finish washers that are part of the handle won't cover the (resulting) oblong holes. Strike three.

OK, nothing new will get done today. I'll just do factory standard stuff. How about the wakeboard racks? They need to be installed. Grab those, thread in the bolts... and the factory bolts are too long. Screw them all the way into the tower, until they're completely seated, and the racks just rattle around nice and loose. Strike four.

None of these problems are insolvable. But it sure is frustrating to take an afternoon off and get absolutely nothing done.

Rant over. Thanks for listening.

I'm way behind on getting our new 24Ve ready for its first season. I only get to work on it for a short time after work on some weeknights. I'm starting to worry I won't be done by July 4th!

So today, I take the afternoon off to dedicate solely to making progress. I have all the tools. I have all the materials. I have an itemized list and a plan.

First up: Build some backing plates for my thruhulls. I measure and discover that the threads aren't long enough to permit the use of backing plates... if I install plates, there won't be enough exposed threads for the valves to screw onto them. Strike one.

OK, might as well start installing the valves and pumps. Oops, no pipe dope. It's at the lake house. Strike two.

Fine, I'll install the custom made grab handle/tow ring that I ordered from the same fab shop that made the original for this boat for Tige. Waited three weeks for it to be made. I tape off the transom, line up the new handle so I can mark for the two new holes that support the tow ring... and discover that the outside studs are too wide. They don't fit in the existing holes, just enough that if I enlarge the holes the finish washers that are part of the handle won't cover the (resulting) oblong holes. Strike three.

OK, nothing new will get done today. I'll just do factory standard stuff. How about the wakeboard racks? They need to be installed. Grab those, thread in the bolts... and the factory bolts are too long. Screw them all the way into the tower, until they're completely seated, and the racks just rattle around nice and loose. Strike four.

None of these problems are insolvable. But it sure is frustrating to take an afternoon off and get absolutely nothing done.

Rant over. Thanks for listening.

Comment