Originally posted by majestic

View Post

Individual 3/4" thru-hulls will work just fine. You can even add an elbow to the ball-valve so the pump lays on it's side.

Putting the pickup in the transom works fine, the only downside IMO, is that you cant fill on the fly.

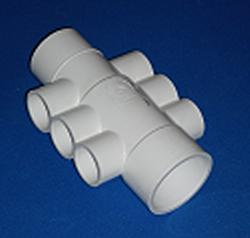

I've done the common manifold and the single shrooms, and it really comes down to which setup will fit best in the bilge so you can orient the pumps in order to avoid vapor-lock.

Comment